Maintaining the differential in your Mercedes-benz W201 is crucial for ensuring smooth operation and longevity of your vehicle. One critical aspect of differential maintenance is understanding and correctly adjusting the pinion shaft friction. This article delves into why pinion shaft friction is important, focusing on the drive and coast sides of the gear teeth and the role of preload in preventing differential issues in your W201.

The pinion and crown wheel, essential components within your W201’s differential, have teeth with specific faces known as the drive and coast sides. The drive side is the face of the tooth that bears the primary load during forward motion – the direction in which your Mercedes-Benz W201 spends most of its operational life. Conversely, the coast side is the opposite face, which engages when the vehicle is in reverse or during deceleration.

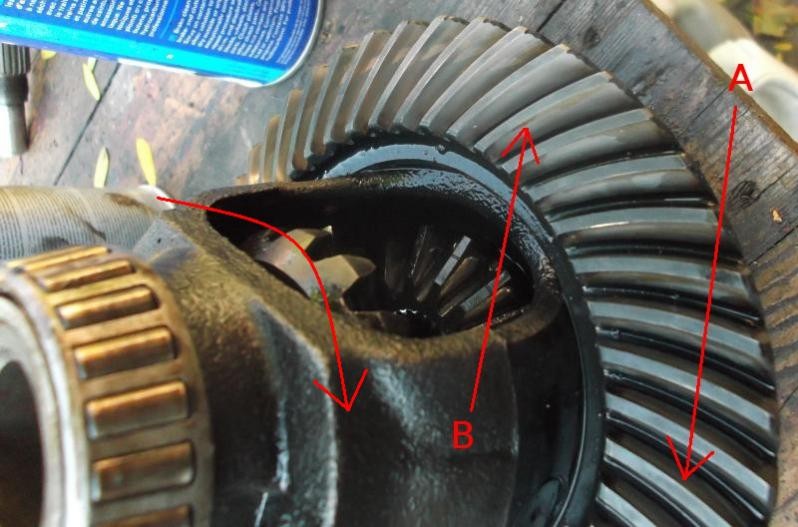

For the crown wheel, the direction of rotation during normal forward travel is illustrated below:

In this image, arrow “A” indicates the drive side of the tooth, while arrow “B” points to the coast side. Understanding these directions is key to grasping how forces are applied within the differential.

Similarly, on the pinion gear, the drive and coast sides are defined by the direction of rotation during forward travel:

Again, arrow “A” marks the drive side and arrow “B” the coast side. The interaction between these teeth requires a slight gap, known as backlash. This backlash is necessary to allow the teeth to roll over each other smoothly. If the teeth were meshed too tightly, the differential would bind and not function.

However, the pressure from the gear teeth interaction creates forces that attempt to push the pinion either towards or away from the crown wheel. During normal forward driving of your Mercedes-Benz W201, the pinion is forced towards the larger tapered roller bearing, moving closer to the crown wheel. Conversely, in reverse, the pinion is pushed towards the smaller tapered roller bearing, away from the crown wheel.

If the pinion nut on the output shaft isn’t correctly tightened, the pinion shaft can shuttle back and forth with every acceleration and deceleration. This movement puts undue stress on the tapered roller bearings, leading to premature wear and potential failure.

Therefore, proper preload on these bearings is essential to prevent this shuttling. Overtightening the pinion nut, however, introduces excessive preload, which also shortens the lifespan of the bearings. Leaving the nut too loose, conversely, increases the likelihood of pinion shaft movement, resulting in impact damage and bearing failure.

In conclusion, ensuring the correct pinion shaft friction and preload is vital for the longevity and reliability of your Mercedes-Benz W201 differential. Precise adjustment protects the tapered roller bearings from unnecessary stress and wear, maintaining the performance and durability of your classic Mercedes-Benz.